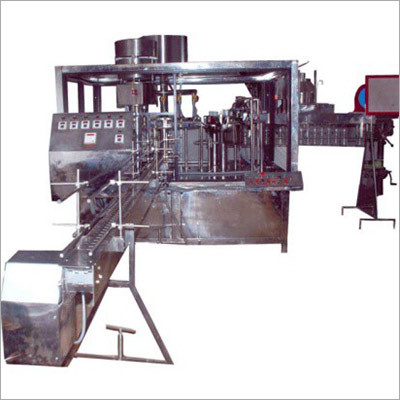

Industrial Water Treatment Plant

Price 150000 INR/ Piece

Industrial Water Treatment Plant Specification

- Warranty

- 1 Year

- Usage & Applications

- Industrial

- Voltage

- 220-440 Volt (v)

- Water Source

- River Water

- Automatic Grade

- Semi Automatic

- Drive Type

- Electric

Industrial Water Treatment Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Industrial Water Treatment Plant

A specialised facility that focuses on treating water used in industrial applications and processes is known as an industrial water treatment plant. In order to improve the effectiveness, quality, and safety of industrial processes, industrial water treatment tries to eliminate impurities, pollutants, and certain compounds. These facilities are made to handle the particular water treatment needs of many sectors of the economy, including manufacturing, power generating, oil and gas, chemical processing, and more.

Typical elements and procedures found in an industrial water treatment facility include the following:

1. Water is received from a variety of sources, including rivers, lakes, wells, and municipal supplies, during intake and pre-treatment. Larger particles, suspended materials, and trash are removed using pre-treatment techniques like screening, sedimentation, and filtration.

2. Chemicals are added to the water to encourage flocculation, the aggregation of tiny particles into bigger flocs. To help create bigger particles, coagulants like aluminium sulphate or ferric chloride are frequently added, then flocculants such polymers.

3. Sedimentation: The water is kept in sizable settling tanks or clarifiers after coagulation and flocculation. Gravity causes the heavier flocs to fall to the bottom and accumulate as a layer of sludge, while the cleaner water rises to the top and is collected.

4. Filtration: The water is filtered to get rid of any pollutants and fine particles that could still be present. Depending on the specific needs and water quality, this can be accomplished using a variety of filtering techniques such as sand filters, multimedia filters, or activated carbon filters.

5. Disinfection: This process is done to get rid of dangerous bacteria and stop microbial growth. Chlorination, UV radiation, ozone treatment, or advanced oxidation processes (AOPs) are a few common disinfection techniques.

6. Chemical Treatment: Depending on the unique industrial processes and water quality, further chemical treatments could occasionally be needed. To address particular problems with water treatment, this may entail pH modification, corrosion inhibitors, scale inhibitors, antifoaming agents, or other chemical additives.

7. Demineralization (Optional): To further remove dissolved particles and minerals from the water, industries that require ultrapure water or a particular water quality may use demineralization procedures like ion exchange or reverse osmosis.

8. Recirculation and reuse: To maximise water use and cut down on overall consumption, water may be recirculated and reused inside the plant depending on the industrial application. Treatment procedures can be modified as necessary to satisfy the unique quality standards for reuse.

9. Effluent Discharge or Environmental Compliance: The treated water is either released into the environment in accordance with legal requirements or is subjected to additional treatment to fulfil needed discharge criteria.

10. Monitoring and control: To continuously assess water quality indicators, flow rates, and system performance, industrial water treatment plants use advanced monitoring systems. To enhance the efficacy of the treatment procedures, guarantee dependability, and adapt to changing circumstances, automation and control systems are used.

Industrial water treatment facilities are built to meet the unique requirements and requirements of the industries they service. Depending on criteria including the type of industry, the quality of the water source, the target water quality, and any applicable regulatory requirements, the treatment procedures and technologies used might vary greatly. For industrial settings, effective and efficient water treatment requires routine maintenance, periodic testing, and system optimisation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mineral Water Processing Plant Category

Packaging Drinking Water Machinery

Price 1050000 INR / Piece

Minimum Order Quantity : 1 Piece

Water Source : Other

Material : Mild Steel

Warranty : 1 Year

Usage & Applications : Industrial

Mineral Water Bottling Plant

Price 830000 INR / Piece

Minimum Order Quantity : 1 Piece

Water Source : River Water

Material : Mild Steel

Warranty : 1 Year

Usage & Applications : Industrial

Mineral Water Plant

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Water Source : River Water

Material : Mild Steel

Warranty : 1 Year

Usage & Applications : Industrial

Water Purification Plant

Minimum Order Quantity : 1 Piece

Water Source : River Water

Material : Mild Steel

Warranty : 1 Year

Usage & Applications : Industrial

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry